Welcome to Parcelconsulting

Welcome to Parcelconsulting

In an era where sustainability is becoming not just a buzzword but a necessity, the logistics industry is undergoing a significant transformation with green warehousing leading the charge. As businesses worldwide strive to minimize their environmental footprint, the adoption of green warehousing practices offers a promising pathway to more sustainable operations. This shift not only catalyzes a reduction in energy consumption and waste production but also propels companies towards meeting stringent regulatory requirements and fostering goodwill among eco-conscious consumers. Understanding the benefits of eco warehousing and the components that make it effective is crucial for organizations looking to adapt and thrive in this new landscape.

In the quest for sustainability within the logistics sector, optimizing warehouse design emerges as a pivotal strategy. This strategy not only aids in environmental conservation but also boosts operational efficiency and cost-effectiveness.

A cornerstone of sustainable warehouse design is the incorporation of energy-efficient infrastructure. Modern warehouses are increasingly leveraging natural light, employing skylights and solar panels to minimize reliance on artificial lighting. Energy-efficient lighting such as LED systems further reduce energy consumption. Advanced technologies, including energy management systems, allow for the strategic operation of machinery, ensuring that energy is utilized only when necessary. Automation plays a significant role in this aspect, with automated equipment reducing the emission of polluting gasses and enabling operations in dark warehouses, thus conserving energy.

The strategic selection of a warehouse location can significantly impact its sustainability. Choosing locations close to urban centers lowers transportation emissions, leading to a reduced carbon footprint. What’s more, by designing warehouses with the future in mind—equipped to adapt to changing needs and challenges—ensures long-term sustainability. This includes creating layouts that optimize the flow of people and materials, minimizing operational bottlenecks and enhancing safety. Employing computer models and flow simulation exercises aids in identifying and addressing potential inefficiencies, paving the way for more sustainable operations.

Sustainable building materials are integral to green warehouse design. These materials, sourced locally to reduce transportation costs, include eco-friendly options such as specialized paints, adhesives, and sealants that lower polluting properties and use fewer chemicals in production. High-density storage systems and the strategic placement of items within the warehouse further maximize space utilization and energy efficiency. Moreover, the use of renewable energy sources, like solar panels, and the implementation of high-volume low-speed (HVLS) fans for air circulation, exemplify the commitment to sustainability through thoughtful material and technology choices.

Optimizing warehouse design for sustainability is a multifaceted endeavor that encompasses energy efficiency, strategic planning, and the use of eco-friendly materials. Adopting these practices allows logistics facilities to markedly lessen their environmental impact, enhance operational efficiency, and future-proof their operations in line with emerging sustainability standards.

Implementing green energy solutions within the logistics sector, particularly in warehousing, is a strategic move towards sustainability. These solutions not only minimize environmental impact but also deliver substantial cost savings and operational efficiencies.

Warehouses are uniquely positioned to benefit from renewable energy sources such as solar, wind, and geothermal energy. The expansive rooftops of warehouses are ideal for solar panel installations, which can drastically reduce electricity bills, accounting for about 15% of total operating costs. In addition to solar power, wind and geothermal energy present viable alternatives, depending on geographic and climatic conditions. These renewable sources not only help in cutting down carbon emissions but also ensure a consistent power supply. Moreover, transitioning to these eco-friendly energy sources can make businesses eligible for government incentives, promoting sustainable living.

Smart energy management systems, driven by the Internet of Things (IoT), are revolutionizing how warehouses manage and consume energy. These systems allow for the monitoring and optimization of energy usage, enhancing operational efficiency and reducing costs. By employing IoT-driven technologies, warehouses can automate their energy consumption patterns, leading to a more sustainable operation. The benefits of integrating smart energy management systems include:

Maximizing the use of natural light within warehouses is a cost-effective and sustainable approach to reducing reliance on artificial lighting. Strategies such as installing skylights, light shelves, and transparent roof panels can transform a warehouse into an energy-efficient space. Moreover, implementing a lighting control system based on timers and sensors can further optimize energy usage. The steps to leverage natural light include:

Integrating green energy solutions in warehousing promotes environmental sustainability, boosts operational efficiency, and lowers costs. Transitioning to renewable energy sources, integrating smart energy management systems, and leveraging natural light are key strategies in achieving these goals. As the logistics sector continues to evolve, embracing these green warehousing practices will be crucial for future-proofing operations and contributing to a more sustainable world.

The integration of smart systems and the adoption of comprehensive recycling programs, coupled with the utilization of sustainable packaging materials, are transformative strategies that significantly contribute to environmental stewardship.

The deployment of Smart Inventory Management Systems (SIMS) marks a significant leap forward in minimizing waste and enhancing operational efficiency. These systems, powered by technologies such as AI, IoT, RFID tags, and barcode sensors, offer precise tracking, swift item identification, and real-time insights into inventory levels. By automating inventory processes, these systems not only streamline workflows but also reduce errors, leading to increased accuracy and faster operations. Moreover, leveraging IoT-driven inventory optimization empowers businesses to uphold ideal stock quantities, effectively mitigating surplus or deficits and enhancing order fulfillment. This tactical approach to inventory control not only strengthens operational efficacy but also substantially reduces wastage, aligning with the ethos of sustainable warehousing practices.

A cornerstone of sustainable warehousing practices is the establishment of robust recycling programs. These initiatives aim to gather, process, and repurpose materials that might otherwise end up in landfills, thus mitigating waste. The benefits of such programs are manifold, including the reduction of environmental impact through the diversion of materials from landfills, substantial cost savings from repurposing materials, and enhanced company image among eco-conscious consumers. Additionally, compliance with regulatory mandates on waste management becomes more manageable with effective recycling strategies in place. Key components of successful recycling programs include the strategic placement of recycle bins to ensure easy access for employees, clear signage to guide recycling efforts, and ongoing education to foster a culture of sustainability within the organization. By prioritizing recycling, warehouses can significantly reduce their ecological footprint while reaping economic benefits.

The escalating use of non-recyclable packaging materials poses a mounting challenge within the logistics industry. Sustainable packaging solutions, such as biodegradable materials and optimized packaging design, offer a viable path to reducing waste and minimizing environmental impact. These practices not only decrease the volume of waste generated but also address the issue of product damage during transit, further reducing the need for returns and reshipments.

In conclusion, advancing inventory and waste management in the context of green warehousing is pivotal for achieving sustainability goals. Through the adoption of smart inventory systems, the implementation of comprehensive recycling programs, and the minimization of packaging waste with sustainable materials, warehouses can significantly reduce their environmental impact. These strategies not only contribute to a greener planet but also offer operational efficiencies and cost savings, highlighting the dual benefits of sustainability initiatives in the logistics sector.

In the rapidly evolving landscape of logistics and supply chain management, leveraging cutting-edge technology has become indispensable for warehouses aiming to stay competitive. Incorporating Artificial Intelligence (AI), the Internet of Things (IoT), and cutting-edge robotics into warehouse functions isn’t merely a passing trend; it represents a strategic leap toward unparalleled efficiency and sustainability. This section delves into how these technologies are reshaping the future of warehousing, focusing on automation and robotics, advanced software solutions, and the synergistic power of AI and IoT for predictive analytics and monitoring.

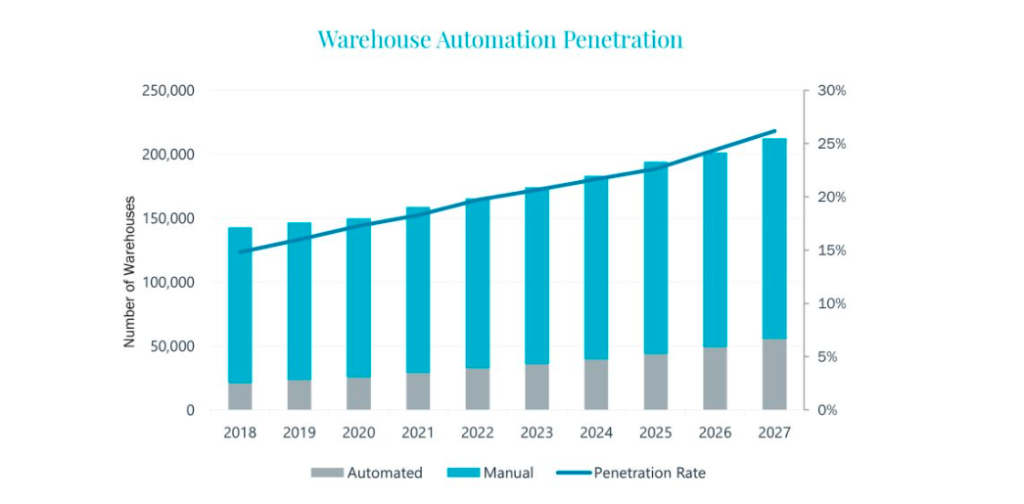

The adoption of robotics in warehousing operations marks a significant leap towards enhancing operational efficiency and energy conservation. Leading the charge in this transformation are Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), executing routine duties with unparalleled precision and swiftness. This not only reduces human error but also significantly enhances productivity. Through workflow optimization, robots play a pivotal role in achieving notable energy efficiencies and decreased operational expenditures. Moreover, the ability of robotic systems to operate in compact, high-density environments enables better space utilization, further reducing the warehouse’s carbon footprint.

Warehouse management systems (WMS) have revolutionized how warehouses operate, offering unparalleled visibility into inventory management and supply chain operations. The implementation of cloud-based WMS solutions allows for seamless management of various system functionalities from a unified platform. This facilitates the prompt rollout of product updates and provides workers with instant access to crucial data. With features like real-time tracking of product locations and advanced reporting and forecasting tools, WMS enables informed decision-making based on the latest data. Furthermore, automation within WMS solutions significantly curtails labor costs while accelerating the overall order fulfillment process.

The synergy between AI and IoT has ushered in a new era of smart warehousing, where data-driven decision-making reigns supreme. The interconnected network of sensors and devices provided by IoT gathers crucial data concerning inventory quantities, environmental parameters, and equipment conditions. AI processes this information to develop actionable insights, enhancing various aspects of warehouse operations. Predictive analytics, powered by AI, facilitates efficient inventory management by forecasting demand and identifying potential stock shortages. AI-powered route optimization and inventory management adjustments guarantee streamlined supply chain operations and heightened customer contentment. Additionally, AI and IoT enhance warehouse security by detecting suspicious activities in real-time, thus safeguarding assets.

In embracing these technological advancements, warehouses are not only achieving greater operational efficiency but are also making significant strides towards sustainability. Automation reduces the need for manual labor and energy consumption, while AI and IoT enable precise monitoring and management of resources, minimizing waste. The continuous refinement of algorithms based on supply chain data ensures that warehouse operations are constantly optimized for both efficiency and environmental stewardship. This strategic integration of technology in warehousing exemplifies how the future of logistics is being shaped by innovation, setting a new standard for green warehousing practices.

In the dynamic world of logistics and warehousing, fostering a culture of sustainability is not just an ethical choice but a strategic necessity. The journey towards a greener future in warehousing operations is paved with the commitment of every team member, from the ground up.

Educating employees about the benefits of green logistics and sustainability is the cornerstone of fostering a culture of sustainability. It’s crucial for team members to grasp how sustainable practices can positively impact both the company and the environment. This includes understanding how these practices lead to waste reduction, resource conservation, emission minimization, and ultimately, cost savings and enhanced operational efficiency. Incorporating concrete examples and case studies can significantly amplify this message, showcasing successful initiatives and inspiring employees.

Involvement in planning and implementation further solidifies this culture. Encouraging input and recommendations regarding process enhancement, systems refinement, and technological advancement fosters a sense of ownership and dedication among employees. Providing resources, tools, and training equips them with the necessary skills to implement green logistics and sustainability practices effectively. Establishing an atmosphere conducive to collaboration nurtures transparent communication, enabling employees to openly share their thoughts, address concerns, and discuss challenges pertaining to sustainable initiatives.

Fostering a culture of ongoing enhancement and responsibility proves pivotal in the triumph of sustainability endeavors. Consistent assessments and revisions of policies and objectives, guided by evolving data analytics and stakeholder needs, guarantee the organization’s sustainability endeavors stay pertinent and effective. By incorporating both financial and non-financial data into comprehensive reports, stakeholders gain a holistic perspective of the organization’s enduring value creation strategy. This approach encourages a balanced decision-making ethos that aligns financial considerations with environmental and social imperatives.

Implementing and monitoring performance through targets and KPIs is critical. Businesses must ensure that benchmarks evolve, metrics are fine-tuned, and there is continuous employee engagement and training. This iterative process supports the establishment of a sustainable supply chain, driving the organization towards its sustainability goals.

The significance of fostering a culture of sustainability cannot be overstated—it’s essential for the longevity and relevancy of the logistics sector. The collective efforts in education, engagement, and continuous improvement in environmental practices represent a beacon of progress for businesses worldwide. The commitment to transparency and accountability serves as the backbone for trust and efficiency in operations. As we move forward, it’s clear that the future of logistics is not just about moving goods but doing so in a manner that ensures prosperity for our planet and societies. The roadmap laid out by green warehousing practices offers a promising route towards a more responsible and sustainable future in logistics and beyond.

Parcel consulting offers specialized knowledge and guidance that can significantly impact the sustainability efforts of warehousing operations. By analyzing shipping data and supply chain logistics, we can identify opportunities for efficiency improvements and carbon footprint reduction.

Our experienced experts offer advice on the selection of eco-friendly packaging materials, optimal transportation routes, and strategies for minimizing delivery times, all of which contribute to greener warehousing practices. We can help warehouses implement innovative technologies like route optimization software and real-time tracking systems, enabling them to make data-driven decisions that prioritize environmental sustainability while maintaining operational effectiveness.